Have a few trees to trim? Or do you need to cut holes in drywall for wires or plumbing? From home improvement and landscaping to woodworking hobbies, saws are one of the best tools to use! They’re also needed for many construction and carpentry projects. But which type of saw should you choose?

You’ll find that there are several different types of handsaws and power saws available. Some are better for cutting through softer material. Others are ideal for cutting through thick or hard materials.

The kind that’s best for you depends on what you’re using it for — and a few other factors. How can you make sure you choose the right saw? We’ll explore the different types to make your decision easier!

What Are the Main Types of Saws?

Saws are generally divided into two main categories — handsaws and power saws. In each category, you’ll find multiple types to choose from.

Hand saws

These are saws that don’t require a power source, such as a battery, electricity, or fuel. You hold the saw in your hand and use your own strength to cut through materials.

Hand saws have many uses, such as:

- Cutting wood for building or home improvement projects, such as cutting moldings

- Cutting wood for woodworking projects

- Trimming bushes, shrubs, and tree branches

Hand saws are lightweight and extremely portable for use virtually anywhere. They also cost much less than power saws, but they may not provide the power or speed you need for larger projects or tasks.

Power Saws

These saws are driven by some kind of power source, such as a gas motor, battery, or electricity. Some power saws are compact and portable, but others are large, stationary machines that are designed for use in a shop. There are also benchtop models, which can be used in a workshop or transported to jobsites.

Power saws can be used for several kinds of projects, such as:

- Cutting through metal, timber, and other thick or hard materials

- Making many different cuts, such as crosscuts or rip cuts with better precision

- Cutting down trees or larger branches

Power saws cut quicker and more smoothly than handsaws, so they tend to be more efficient. They cost more than handsaws, and require extreme care and even training to use safely.

Hand Saws

What types of hand saws are there? You can find all kinds — whether you to cut drywall, prune tree branches, or make fine cuts in decorative moldings. Here are several commonly used hand saws:

1. Back Saw

This saw offers enhanced control and super-smooth cuts thanks to its small, sharp teeth; thin blade; and metal spine that runs along the top edge of the blade. It’s mainly used for cutting dovetail joints or in a miter box for trimming wood moldings. They may not be as versatile as other hand saws, but its invaluable for making ultra-precise, smooth cuts.

Choose this saw if: you need to cut dovetail joints or moldings with better precision.

2. Bow Saw

This hand saw, with its large, aggressive-cutting teeth, is designed to quickly cut down trees and prune branches. And it’s everyone’s go-to tool for cutting down Christmas trees. But those aren’t it’s only uses: Bow saws are durable enough to cut through thick timber or logs. The saw’s large, curved handle also makes bow saws extremely comfortable to use, as opposed to some handsaws.

Choose this saw if: you need to cut logs or prune bushes and trees.

3. Crosscut Saw

These saws have a thick blade and bigger teeth, which are designed for quickly cutting across the width of a board, perpendicular to the woodgrain. Crosscut saws are suitable for both carpentry and landscaping work. They’re also an all-purpose saw with a lot of versatility. Crosscut saws are affordable, strong and durable — but they do require enough physical stamina to use when cutting thicker pieces of wood or lumber.

Choose this saw if: you need to trim shrubs or small tree branches, cut lumber, or make rougher cuts in pieces of wood.

4. Drywall Saw

These small hand saws have short blades with large, super-sharp teeth that are designed for cutting through drywall and plaster. That may limit their overall use, but they’re an excellent choice when making holes or cuts in narrower spaces. Drywall saws have thick, short blades with a tapered tip, which allows you to poke through the surface prior to sawing. Some have teeth on the top and bottom for making cuts on both sides of drywall. Drywall saws can also be used to cut thin plywood and wood paneling, but be aware that they’ll leave behind a very rough cut.

Choose this saw if: you need to cut through drywall or panels.

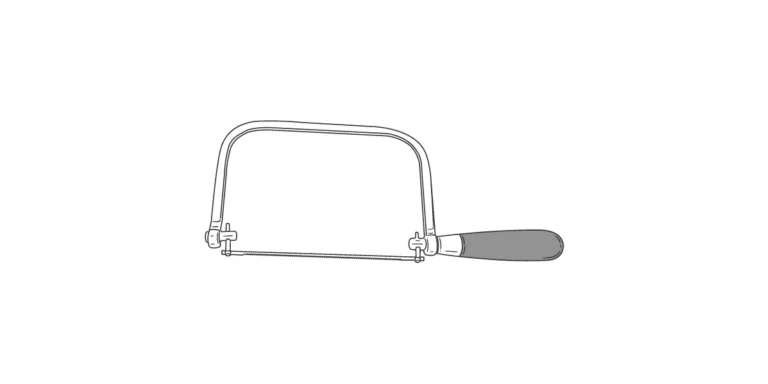

5. Fret Saw

This type of hand saw offers incredible accuracy for making intricate or curved cuts for decorative woodwork. A fret saw is very similar to a coping saw, which is commonly used to make crosscuts and coping cuts in decorative moldings. These types of handsaws have very thin, narrow blades with over 30 teeth per inch on the blade for producing incredibly smooth cuts.

Choose this saw if: you need to make intricate cuts in wood.

6. Hacksaw

As one of the most common handsaws, hacksaws are specifically designed for cutting various metals, including copper pipes and metal tubing. These saws have thin blades with very fine teeth, and a strong, high-tension steel frame. Hacksaws come in many different designs and in a wide range of prices. However, it’s best to pay a little extra for a model that has a heavy-duty frame, easy-to-adjust blade-tensioning mechanism, and an enclosed handle to protect against bruised knuckles.

Choose this saw if: you need to saw through metal.

7. Rip Saw

Rip saws are designed for cutting along the length of a board, parallel to the woodgrain. Rip-cut saws have fewer teeth than other handsaws, but they’re sharp enough to cut–or rip–through the woodgrain. The durability and design of these saws make them suitable for all kinds of wood-cutting jobs.

Choose this saw if: you need to cut wood with the grain rather than across it.

Power Saws

What types of power saws are there? As with hand saws, you’ll find multiple ones to consider using. But the right choice for your project or task depends on what you’re cutting and what types of cuts you’re making. Here are are some of the most popular power saws:

1. Chop Saw

These power saws are used exclusively to make square cuts in metal, including flat stock and tubing. They typically use a toothless aluminium-oxide abrasive blade. The saws are also equipped with an integral clamp to securely hold the workpiece in place during cutting.

Choose this saw if: you need to cut metal.

2. Circular Saw

A portable circular saw is an essential carpenter’s tool, but can also be used in the woodshop. And when fitted with the appropriate blade, a circular saw can be used to cut through many different materials, including wood, plywood, metal, fiberglass and plastic. The two most popular sizes of circular saws use either a 7 1/4-in. or 8 1/4-inch diameter blade, though some models accept blades as small as 4 1/2 inches and as large as 16 inches! Circular saws have retractable blade guards for safety, and on-board mechanisms for adjusting the depth-of-cut and bevel angle. Both corded electric and battery-powered cordless models are available.

Choose this saw if: you need a portable saw to cut wood, plastic, metal, or other materials.

3. Compound Miter Saw

A compound miter saw is a benchtop power tool that provides a safe and extremely accurate way to make square crosscuts, angled miter cuts, bevel cuts, and compound-angle cuts in wood. It features a large circular blade–typically 10 or 12 in. dia.–that you pivot down into the workpiece. This setup makes it easier to achieve more precise cuts — whether you’re making straight, compound, angled, or mitered cuts. These saws are powerful and durable, but can be difficult to transport due to their weight and bulk.

Choose this saw if: you need a saw that offers better control for different kinds of cuts, such as compound or angled cuts.

4. Jigsaw

This type of power saw has a short, straight blade that can make straight and curved cuts in a wide variety of building materials. It’s lightweight, extremely portable, and very safe and easy to use on the jobsite or in the shop. When fitted with a very narrow scrolling blade, a jigsaw can cut very tight spirals and curves. It’s also great for plunging into material to make interior cutouts. Be sure to install the appropriate blade for the material you’re cutting. And note that while you can cut relatively straight lines with a jigsaw, for perfectly straight lines, use a circular saw and straightedge guide. Both corded electric and battery-powered cordless models are available.

Choose this saw if: you need to make curved or straight cuts in wood, plywood, metal or plastic.

5. Slide-Compound Miter Saw

A slide-compound miter saw is similar to a compound miter saw, except that its motor and blade slide on steel rods. As a result, it has a much greater capacity. For example, a 10-in. compound miter saw has a crosscut capacity of about 5 1/2 in. wide. A 10-in. slide-compound miter saw can crosscut a board up to about 11 1/4 inches! The saw blade can adjust for making square crosscuts, angled miter cuts, bevel cuts, and compound-angle cuts in wood. These saws are powerful, but because of their weight, they can be difficult to carry without help.

Choose this saw if: you need to make angled cuts in wood or other materials.

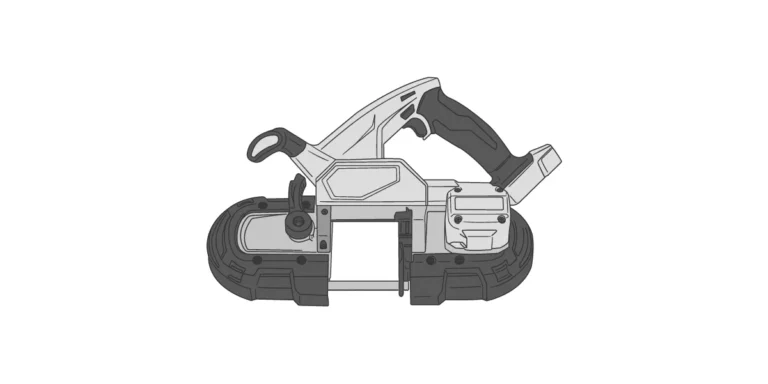

6. Portable Band Saw

This metal-cutting power saw can easily be carried from one place to another, unlike a stationary band saw. It has a powerful motor that drives continuous band-saw blade around two wheels. Simply squeeze the trigger and then set the running blade onto the metal workpiece. Portable band saws can cut through metal pipe, flat stock, tubing and similar metal items with ease. Both corded electric and battery-powered cordless models are available.

Choose this saw if: you need to make cuts in metal pipes and or similar objects.

7. Reciprocating Saw

A reciprocating saw is one of the most indispensable and versatile portable power saws ever invented. When fitted with the proper blade, it can cut through virtually any building material, including wood, plywood, metal, plastic, roof shingles, fiberglass, even nail-embedded wood. It accepts blades ranging in length from about 3 inches to 12 inches. Reciprocating saw blades move quickly and cut very aggressively, so be sure to grip the tool securely. This type of saw is designed for home-remodeling, rough carpentry, and demolition work, not for making precise cuts. Both corded electric and battery-powered cordless models are available.

Choose this saw if: you need a portable saw for smaller projects involving wood or metal.

8. Stationary Band Saw

This type of stationary bandsaw is designed for use in a workshop, where it excels at cutting wood, metal and plastics. It accepts a wide range of blades to match the type of material and the type of cut you need to make: straight or curved. These band saws can create custom cuts and be used with multiple materials, including metal. But they do tend to cost more than other power saws. Both floor-standing and benchtop models are available.

Choose this saw if: you need to make cuts of a few inches or less in plastic, metal, or other materials.

9. Table Saw

This stationary power saw has a circular blade that comes up through a slot in the table — providing a steady work surface for cutting. Hand cranks allow you to adjust both the height and bevel angle of the blade. Table saws are also available as compact benchtop models that you can carry from the shop to the job site. Many of these saws are on the expensive side and need a lot of space, but they deliver a high level of accuracy.

Choose this saw if: you need to make straight, long cuts in wood or other material with a high amount of precision.

Best Saw for Cutting Wood

Types of saws for wood can vary, depending on whether you’re doing a woodworking project or landscaping. Do you need to make fine cuts in wood? Or are you looking for a saw that helps you cut through big branches?

- Backsaws, fret saws and hacksaws with fine teeth are the best for making small, precise cuts

- Circular saws and reciprocating saws are the best power saws for cutting through lumber and plywood

- Bow saws are the best hand saw for pruning larger trees

- Reciprocating saws are the best power saw for demolition work and rough cutting lumber

Best Saw for Beginners

Not familiar working with saws? Some can be difficult — or even dangerous — to operate for beginners. But some are perfect if you’re just starting out with using saws around the house, yard, or workshop.

- Crosscut saws, rip saws and back saws are straightforward and simple hand saws to use for different projects

- Compound miter saws and slide compound miter saws are easier and safer to use for small and large projects compared to portable circular saws and other power saws

- Jigsaws are affordable, and safe and easy to use, making them ideal for novice DIYers

Saw Tips from the Professionals

Knowing which saw you need is the first step. After that, you’ll also need to know how to safely use saws — whether it’s a handsaw or power saw. And you’ll need to cut carefully to get the results you want. That’s where the following tips come in handy!

Beginner Tips for Hand Saws

These saws are fairly easy to use. But how can you ensure you’re using them safely and making the cuts you need? Follow these tips for using hand saws.

- Always use the saw with your dominant hand for better control and maneuvering

- Hold your elbow near your body to keep the blade straight and stop it from becoming tilted

- Mark your cut line and align the blade with it on the scrap side, not right on the center of the line

- Hold the saw at a 45-degree angle to the wood or material

- Use lower angles for finer cuts

- Start with long, smooth strokes using the full blade length

- Make shorter strokes when you’re close to the end of the cut

- Be sure to support both ends of the board to prevent it from falling and splitting before cutting all the way through

Beginner Tips for Power Saws

Power saws may take some getting used to, depending on the kind you’re using and what you’re using it for. The following tips can help you get started with using these types of saws.

- Mark cut lines to use as a guide while cutting

- Use masking tape or painter’s tape on the cut lines to lower the risk of splintering

- Use clamps to hold your material securely at your workstation

- Choose the right blade for your power saw, depending on the material you’re cutting and the cuts you need

- Move the saw on the scrap side of your cut lines instead of right on it

- Avoid pushing the saw to avoid straining the motor

- Remove the blade and start over if you accidentally veer away from your cut lines — don’t curve the saw back toward the cut lines

- Keep both hands on the saw at all times

- Wait for the saw to stop before you remove it from the material

- Unplug the saw or remove its battery before making any adjustments

Dust Collection Tips

Sawing produces a lot of dust that can irritate your lungs and eyes. This sawdust can also end up coating nearby surfaces — giving you a time-consuming cleanup job. But the following tips from professionals can help you prevent these problems:

- Enclose a stationary power saw with a 4-inch hole then use a wet/dry vacuum to collect dust

- Use smooth, large diameter hoses to get maximum airflow

- Minimize the use of flex tubing

- Vent dust outside into a bucket with a separator — not just a bag

- Consider using a wet/dry vacuum for jobsite saws due to their static pressure

- Avoid over-enclosing the saw to ensure motor cooling

- Use a cyclone separator for more efficient dust collection

- Wear a dust mask or dual-cartridge respirator, even with a dust-collection system

- Upgrade to pleated filters, such as Wynn Environmental

- Refer to Bill Pentz’s website (billpentz.com) for dust collection system design as needed

Ready to start your project? With helpful tips from professionals and knowledge of different types of saws, you can confidently use the right one for the job. Always remember to wear safety goggles and follow other safety rules to lower the risk of injuries and accidents.