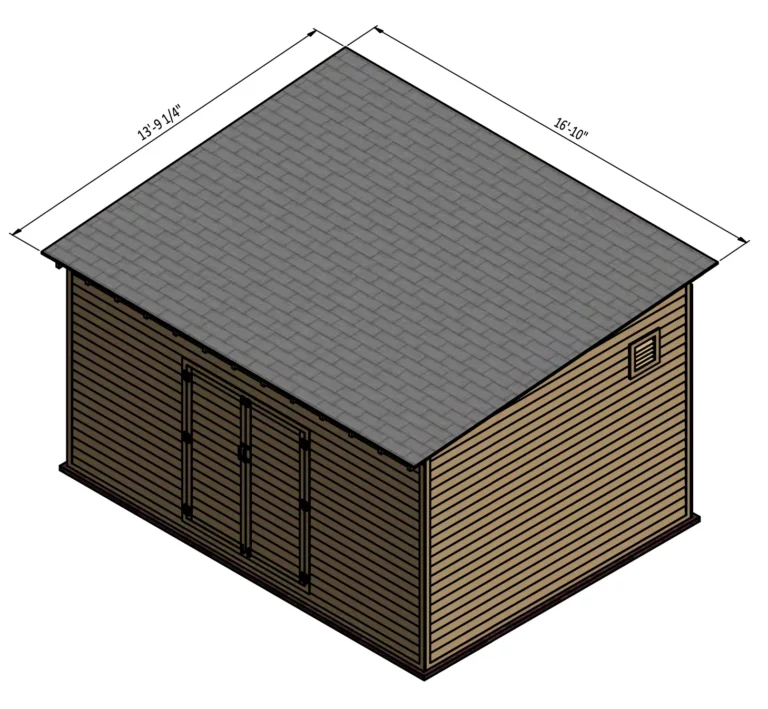

In this article, we are going to teach you how to build a 12×16 lean-to storage shed, perfect for adding extra storage space to your property. Whether you need a place to store gardening tools, lawn equipment, seasonal decorations, or simply want to declutter your garage, this well-designed storage shed will provide ample space while enhancing the look of your yard.

| 12’x16′ storage shed cutting list | ||||

| Site Preparation | Unit | Qty | Size | Note |

| Concrete | Yd3 | 3,2 | ||

| Clay bricks | pcs | 225 | 3 5/8″ x 2 1/4″ x 8″ | |

| Shed’s Bottom Frame | Unit | Qty | Size | Note |

| Pressure-Treated Lumber (1 1/2″ x 7 1/4″) | pcs | 13 | 11′-9″ | Joists |

| Pressure-Treated Lumber (1 1/2″ x 7 1/4″) | pcs | 2 | 16′ | Rim joists |

| Plywood (9/16″) | pcs | 6 | 4’x8′ | Floor sheathing |

| Shed’s Front Wall Frame | Unit | Qty | Size | Note |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 3 | 1′-1″ | Cripple studs |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 2 | 5′-4″ | Bottom plate |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 6 | 7′-3″ | Studs |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 1 | 16′ | Top plate |

| Pressure-Treated Lumber (3 1/2″ x 3 1/2″) | pcs | 1 | 5′-4″ | Door Header |

| Pressure-Treated Lumber (3 1/2″ x 3 1/2″) | pcs | 4 | 7′-3″ | Studs |

| Shed’s Back Wall Frame | Unit | Qty | Size | Note |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 1 | 16′ | Top plate |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 1 | 16′ | Bottom plate |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 11 | 8′-3″ | Studs |

| Pressure-Treated Lumber (3 1/2″ x 3 1/2″) | pcs | 2 | 8′-3″ | Studs |

| Shed’s Side Wall Frame (2x) | Unit | Qty | Size | Note |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 10 | 7′-3″ | Studs |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 1 | 11′-5″ | Top plate |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 1 | 11′-5″ | Bottom plate |

| Shed’s Top Frame | Unit | Qty | Size | Note |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 2 | 11′-8 1/2″ | Top plate |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 1 | 15′-5″ | Top plate |

| Shed’s Roof | Unit | Qty | Size | Note |

| Pressure-Treated Lumber (3/4″ x 6″) | pcs | 2 | 16′ | Fascia |

| Pressure-Treated Lumber (3/4″ x 7 1/4″) | pcs | 2 | 16′ | Fascia |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 2 | 2 3/4″ | Gable wall Stud |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 2 | 4 1/4″ | Gable wall Stud |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 2 | 5 3/4″ | Gable wall Stud |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 2 | 7 1/4″ | Gable wall Stud |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 2 | 8 3/4″ | Gable wall Stud |

| Pressure-Treated Lumber (1 1/2″ x 5 1/2″) | pcs | 13 | 13′-3 1/4″ | Rafters |

| Plywood (9/16″) | pcs | 1 | 5′-9 1/4″ x 1′-9 3/4″ | Roof sheathing |

| Plywood (9/16″) | pcs | 1 | 1′-9 1/4″ x 7′-1 1/4″ | Roof sheathing |

| Plywood (9/16″) | pcs | 1 | 1′-9 1/4″ x 7′-11 1/4″ | Roof sheathing |

| Plywood (9/16″) | pcs | 1 | 8′ x 1′-9 3/4″ | Roof sheathing |

| Plywood (9/16″) | pcs | 3 | 4′ x 7′-1 1/4″ | Roof sheathing |

| Plywood (9/16″) | pcs | 3 | 4′ x 7′-11 1/4″ | Roof sheathing |

| Building paper (#15) | roll | 4 | ||

| Asphalt shingles (250# per sq. min) | ft2 | 235 | ||

| Metal drip edge | ft | 50 | ||

| Side Wall Exterior Siding (2x) | Unit | Qty | Size | Note |

| Pressure-Treated Lumber (1/4″ x 3/4″) | pcs | 1 | 11′-7″ | Starter course |

| Pressure-Treated Lumber (3/4″ x 2 1/2″) | pcs | 1 | 11′-7″ | Trim |

| Pressure-Treated Lumber (3/4″ x 2 1/2″) | pcs | 1 | 8′-7 3/4″ | Trim |

| Pressure-Treated Lumber (3/4″ x 2 1/2″) | pcs | 1 | 9′-7 1/4″ | Trim |

| Wood siding boards (1/2″ x 6″) | ft2 | 105 | 11′-7″ | Siding |

| Back Wall Exterior Siding | Unit | Qty | Size | Note |

| Pressure-Treated Lumber (1/4″ x 3/4″) | pcs | 1 | 15′-8 1/2″ | Starter course |

| Pressure-Treated Lumber (3/4″ x 2 1/2″) | pcs | 2 | 9′-1″ | Trim |

| Pressure-Treated Lumber (3/4″ x 2 1/2″) | pcs | 1 | 15′-8 1/2″ | Trim |

| Wood siding boards (1/2″ x 6″) | ft2 | 145 | 15′-8 1/2″ | Siding |

| Front Wall Exterior Siding | Unit | Qty | Size | Note |

| Pressure-Treated Lumber (1/4″ x 3/4″) | pcs | 1 | 15′-8 1/2″ | Starter course |

| Pressure-Treated Lumber (3/4″ x 2 1/2″) | pcs | 2 | 5′-9″ | Door Trim |

| Pressure-Treated Lumber (3/4″ x 2 1/2″) | pcs | 2 | 6′ | Door Trim |

| Pressure-Treated Lumber (3/4″ x 2 1/2″) | pcs | 2 | 8′-1″ | Trim |

| Pressure-Treated Lumber (3/4″ x 2 1/2″) | pcs | 1 | 15′-8 1/2″ | Trim |

| Wood siding boards (1/2″ x 6″) | ft2 | 95 | 15′-8 1/2″ | Siding |

| Shed’s Door (2x) | Unit | Qty | Size | Note |

| Pressure-Treated Lumber (1/4″ x 3/4″) | pcs | 1 | 2′-2 3/4″ | Starter course |

| Pressure-Treated Lumber (3/4″ x 2 1/2″) | pcs | 2 | 2′-2 3/4″ | Trim |

| Pressure-Treated Lumber (3/4″ x 2 1/2″) | pcs | 2 | 5′-11 3/4″ | Trim |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 2 | 2′-3/4″ | Girts |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 2 | 5′-11 3/4″ | Girts |

| Plywood (9/16″) | pcs | 1 | 2′-7 3/4 x 5′-11 3/4″ | Door sheathing |

| Wood siding boards (1/2″ x 6″) | ft2 | 13 | 2′-2 3/4″ | Siding |

| Door Ramp | Unit | Qty | Size | Note |

| Pressure-Treated Lumber (1 1/2″ x 1 1/2″) | pcs | 5 | 1′-8″ | Girts |

| Pressure-Treated Lumber (1 1/2″ x 2 1/2″) | pcs | 5 | 3′-3/4″ | Girts |

| Pressure-Treated Lumber (1 1/2″ x 2 1/2″) | pcs | 1 | 5′-9″ | Girts |

| Pressure-Treated Lumber (1 1/2″ x 3 1/2″) | pcs | 5 | 6 1/4″ | Girts |

| Plywood (9/16″) | pcs | 2 | 9 1/4″ x 2′-9 1/2″ | Ramp sheathing |

| Plywood (9/16″) | pcs | 1 | 3′-3/4″ x 5′-9″ | Ramp sheathing |

| Fasteners & Hardware | Unit | Qty | Size | Note |

| Door hinge (3″) | pcs | 6 | ||

| Door pull (6″) | pcs | 2 | ||

| Surface bolt (4″) | pcs | 4 | ||

| Wood square louver gable vent (12″ x 12″) | pcs | 2 | ||

| Galvanized nails (2″) | pcs | 4450 | ||

| Wood screws (1″) | pcs | 300 | ||

| Wood screws (2″) | pcs | 1000 | ||

| Wood screws (3″) | pcs | 1500 | ||

| Wood screws (5″) | pcs | 600 | ||

| 12’x16′ storage shed shopping list | ||||

| Materials | Unit | Qty | Size | Note |

| Pressure-Treated Lumber 1″x2″ | pcs | 1 | 12′ | Starter course |

| Pressure-Treated Lumber 1″x2″ | pcs | 2 | 16′ | Starter course |

| Pressure-Treated Lumber 1″x2″ | pcs | 1 | 6′ | Starter course |

| Pressure-Treated Lumber 1″x3″ | pcs | 1 | 12′ | Trim |

| Pressure-Treated Lumber 1″x3″ | pcs | 6 | 10′ | Trim |

| Pressure-Treated Lumber 1″x3″ | pcs | 2 | 16′ | Trim |

| Pressure-Treated Lumber 1″x3″ | pcs | 7 | 6′ | Door Trim, Trim |

| Pressure-Treated Lumber 1″x8″ | pcs | 4 | 16′ | Fascia |

| Pressure-Treated Lumber 2″x2″ | pcs | 2 | 6′ | Girts |

| Pressure-Treated Lumber 2″x3″ | pcs | 3 | 8′ | Girts |

| Pressure-Treated Lumber 2″x3″ | pcs | 1 | 6′ | Girts |

| Pressure-Treated Lumber 2″x4″ | pcs | 11 | 6′ | Cripple studs, Bottom plate, Gable wall |

| Pressure-Treated Lumber 2″x4″ | pcs | 23 | 8′ | Studs, Gable wall stud, Girts |

| Pressure-Treated Lumber 2″x4″ | pcs | 4 | 16′ | Top plate, Bottom plate |

| Pressure-Treated Lumber 2″x4″ | pcs | 13 | 10′ | Studs, Gable wall stud |

| Pressure-Treated Lumber 2″x4″ | pcs | 4 | 12′ | Top plate, Bottom plate |

| Pressure-Treated Lumber 2″x6″ | pcs | 13 | 14′ | Rafters |

| Pressure-Treated Lumber 2″x8″ | pcs | 13 | 12′ | Joists |

| Pressure-Treated Lumber 2″x8″ | pcs | 2 | 16′ | Rim joists |

| Pressure-Treated Lumber 4″x4″ | pcs | 1 | 6′ | Door Header |

| Pressure-Treated Lumber 4″x4″ | pcs | 4 | 8′ | Studs |

| Pressure-Treated Lumber 4″x4″ | pcs | 2 | 10′ | Studs |

| Plywood (9/16″) | pcs | 20 | 4′x8′ | Sheating |

| Poured concrete | lbs | 7 | 60 | |

| Concrete Brick Pavers | pcs | 225 | 3 5/8″ x 2 1/4″ x 8″ | |

| Building paper (#15) | roll | 4 | ||

| Asphalt shingles (250# per sq. min) | ft2 | 235 | ||

| Metal drip edge | ft | 50 | ||

| Wood siding boards (1/2″ x 6″) | ft2 | 13 | 2′-2 3/4″ | Siding |

| Wood siding boards (1/2″ x 6″) | ft2 | 105 | 11′-7″ | Siding |

| Wood siding boards (1/2″ x 6″) | ft2 | 240 | 15′-8 1/2″ | Siding |

| Door hinge (3″) | pcs | 6 | ||

| Door pull (6″) | pcs | 2 | ||

| Surface bolt (4″) | pcs | 4 | ||

| Wood square louver gable vent (12″ x 12″) | pcs | 2 | ||

| Galvanized nails (2″) | pcs | 4500 | ||

| Wood screws (1″) | pcs | 300 | ||

| Wood screws (2″) | pcs | 1050 | ||

| Wood screws (3″) | pcs | 1500 | ||

| Wood screws (5″) | pcs | 600 |

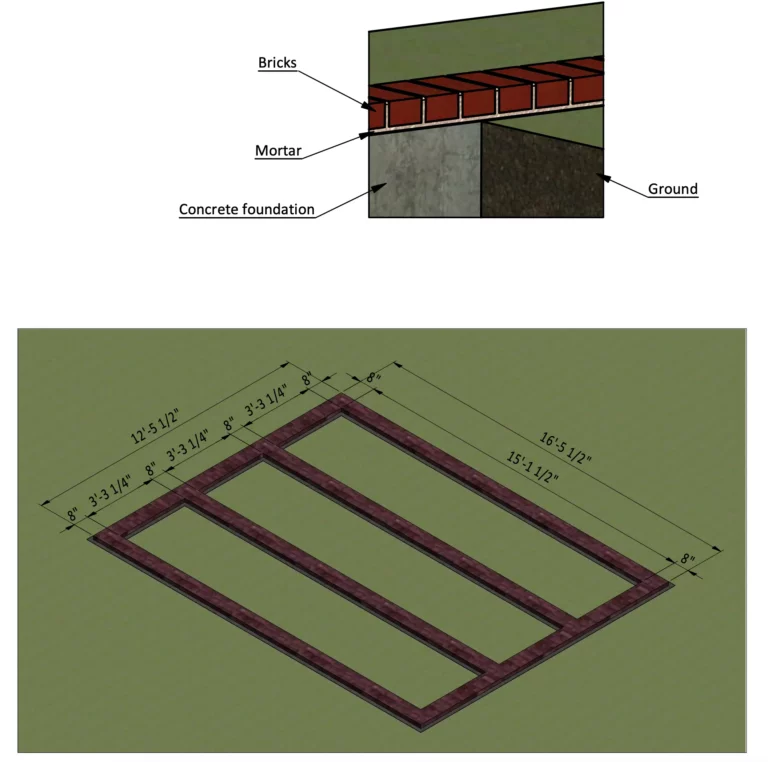

Step 1: Ground Works

1.1 Clear the area where you want to build the shed and layout for the foundation, using the illustration shown below.

1.2 For the foundation, start by digging each of the six trenches at least 1′ wide and 1′ deep. If you live in a cold-weather region, you may need to dig down to the frostline; check with the local building department for specific requirements.

Step 2: Foundation Preparation

2.1 After excavating the trenches, fill them level with the ground with concrete. Allow the concrete to cure overnight.

2.2 Once the concrete has cured, mix up a batch of mortar and lay one layer of standard-sized bricks across the foundation. Trowel mortar between each brick, creating ⅜-inch-wide mortar joints. You will need roughly 255 bricks for this step.

Step 3: Framing the Floor

3.1 Assemble the shed’s floor frame using pressure-treated 2x8s. Cut two 2x8s to 16′ and two more to 11′-9″. These four boards will form the perimeter rim joists.

3.2 Secure the joists with 3” decking screws.

3.3 Use a carpenter’s framing square to ensure the corners are 90°. Or, try this technique: Measure the diagonal distance from one corner to the other. Then, repeat to measure the diagonal distance across the opposite two corners. When the two dimensions are the same, the floor frame is square.

Step 4: Framing the Floor

4.1 Cut 11 pressure-treated 2x8s to 11′-9″. These will serve as the shed’s floor joists.

4.2 Fasten the floor joists by driving 3” decking screws through the rim joists and into the ends of each floor joist.

4.3 Use a carpenter’s framing square to ensure the corners are 90°. Or, measure the diagonal distance from one corner to the other. Then, repeat to measure the diagonal distance across the opposite two corners. When the two dimensions are the same, the floor frame is square.

Step 5: Install the Plywood Floor

5.1 Cover the floor frame with 5/8″ exterior-grade plywood, as shown below. You will need six 4′ x 8′ sheets.

5.2 Secure the plywood to the joists with 2″ screws.

Step 6: Assemble Front Wall Frame

6.1 Using pressure-treated 2x4s and 4x4s, construct the front wall frame, as shown below. You will need six 2×4 wall studs cut to 7′-3″, two 2×4 bottom plates cut to 5′-4″, one 2×4 cut to 16′ for the wall’s top plate. Next, cut the 4×4 door header to 5′-4″, and three 2x4s to 1′-1″ to serve as the cripple studs that get installed between the header and top plate. Then cut two 4x4s to 7’-3” that are used as trimmer studs to form the rough opening for the doorway.

6.2 Fasten the wall studs with 3″ decking screws, and use 5” structural screws to secure the header to the trimmer studs.

6.3 Using a carpenter’s square, check the corners to make sure they are 90°. Or, measure the opposing corner-to-corner diagonal distances to ensure the wall frame is square.

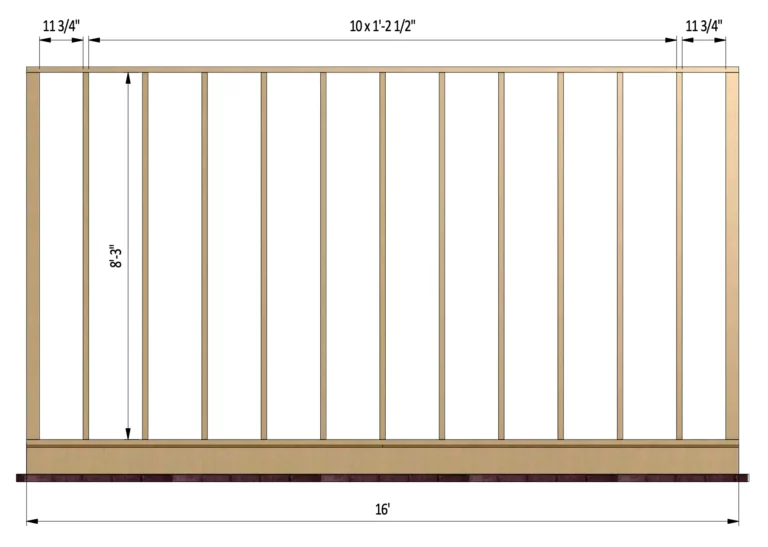

Step 7: Assemble Back Wall Frame

7.1 Build the shed’s back wall out of pressure-treated 2x4s and 4x4s. Cut eleven 2×4 wall studs to 8′-3″, and two 2x4s to 16′ to form the top and bottom wall plates.

7.2 Connect the wall frame parts with 3″ decking screws.

7.3 Using a speed square or carpenter’s square, check the corners to make sure they are 90°. Or, measure the opposing corner-to-corner diagonal distances to ensure the wall frame is square.

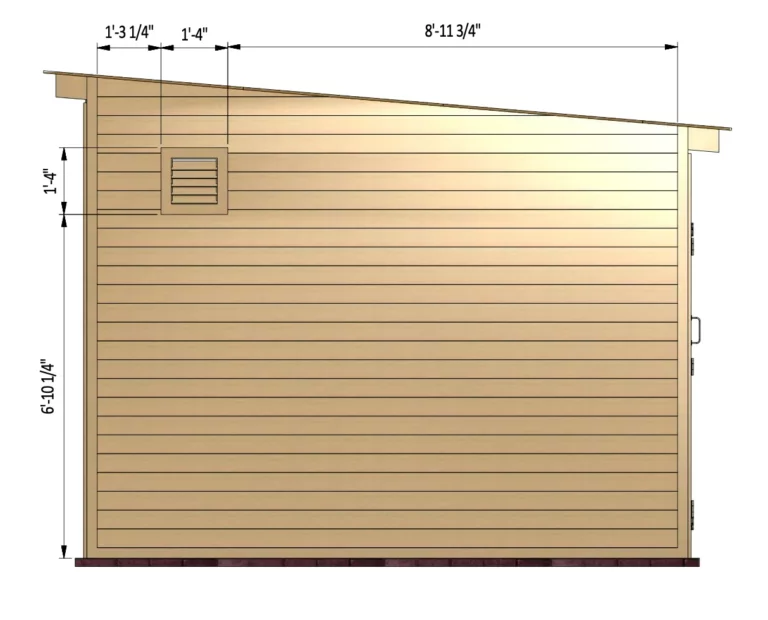

Step 8: Assemble Right and Left Wall Frames

8.1 Next, use pressure-treated 2x4s to build the left and right side walls of the shed, which are identical in size. For each side wall, cut ten 2×4 wall studs to 7′-3″, and two 2x4s to 11′-5″ that will be the top and bottom plates.

8.2 Fasten together each wall frame with 3″ screws.

8.3 Using a carpenter’s square, check the corners to make sure they are 90°. Or, measure the opposing corner-to-corner diagonal distances to ensure the wall frame is square.

8.4 Stand up each wall frame on the floor deck and then use 3” screws to fasten them down to the floor and to each other at all four corners.

Step 9: Assemble the Top Beams

9.1 Double-up the top plate on the front and two side walls by cutting one pressure-treated 2×4 to 15′-5” and two 2x4s cut to 11′-8 1/2″.

9.2 Fasten the 2x4s to the top wall plates with 3″ decking screws.

9.3 Using a carpenter’s square, check the corners to make sure they are 90°. Or, measure the opposing corner-to-corner diagonal distances to ensure the wall frame is square.

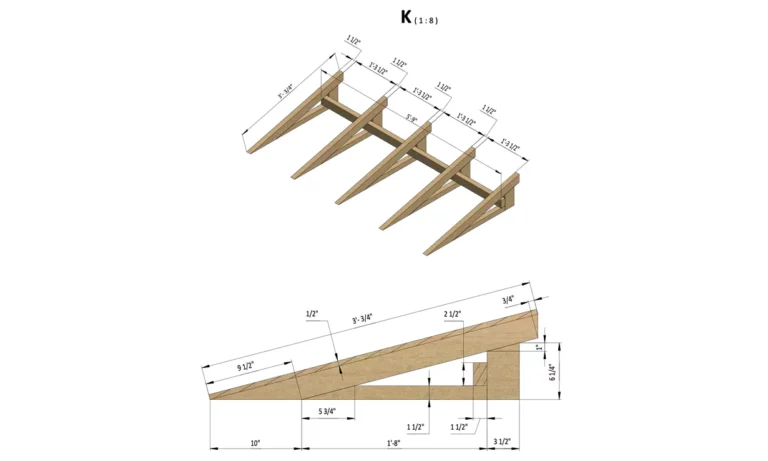

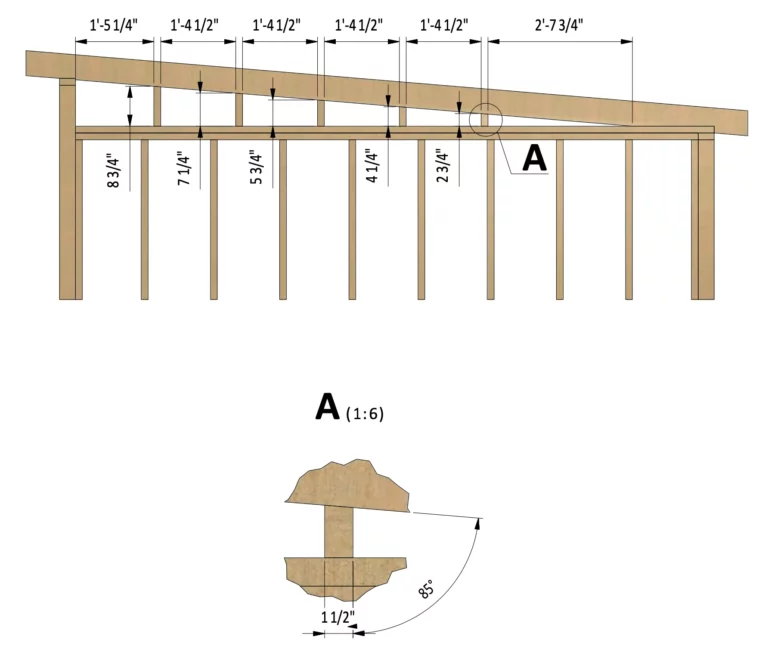

Step 10: Assemble the Roof Frame

10.1 Using pressure-treated 2x6s, cut thirteen roof rafters 13′-3 1/4″ long according to the drawing below. Cut a bird-mouth notch in each end of all the rafters so they will sit flush on top of the front and rear walls.

10.2 Connect the rafters to the top wall plates with 3″ screws.

Step 11: Assemble the Gable Wall Studs

11.1 Cut pressure-treated 2×4 studs to fit between the top plate and the underside of the rafters on the two gable-end walls of the shed. For each wall, cut five 2x4s, as shown in the illustration below. So, you will need a total of 10 studs: cut to 8 3/4″, two to 7 1/4″, two cut to 5 3/4″, two to 4 1/4″ and two to 2 3/4″. Be sure to bevel-cut the top of each stud to match the roof slope of the rafters.

11.2 Fasten the studs with 3″ screws.

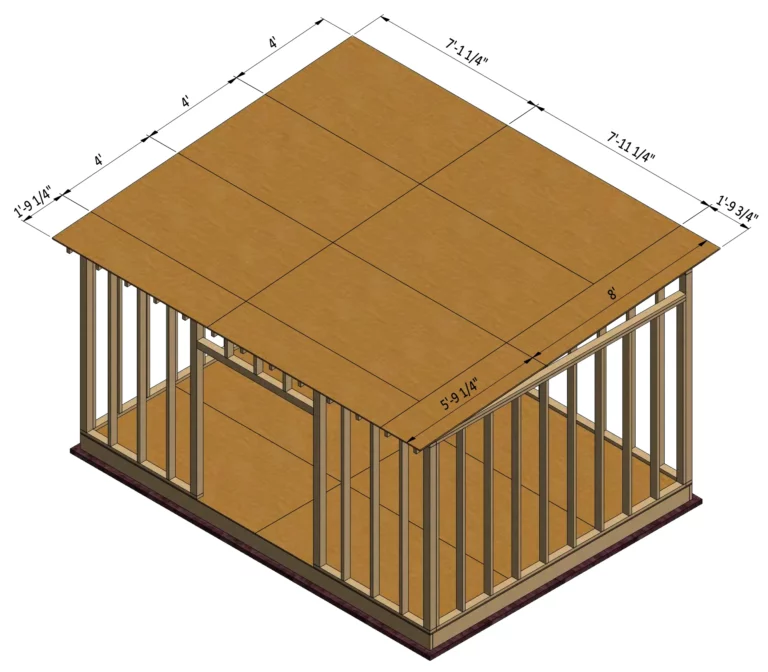

Step 12: Install Plywood for the Roof

12.1 Cut sheets of 5/8″ plywood for the roof sheathing using the drawing below as a guide. You will need a total of 10 pieces: three measuring 4’ x 7′-1 1/4″, three at 4’ x 7′-11 1/4”, one at 1′-9 1/4″ x 7′-1 1/4″, one at 1′-9 1/4″ x 7′-11 1/4″, one at 1′-9 3/4″ x 8′, and one at 1′-9 3/4″ x 5′-9 1/4″.

12.2 Secure the plywood to the rafters with 2″ wood screws.

Step 13: Installing the Exterior Siding to the Left and Right Walls

13.1 Cut pressure-treated 1x3s to create trim boards to be installed at each corner of the shed, and along the bottom of the walls. Using the illustration below as a reference, cut one 1×3 cut to 9′-7 1/4″ for the corner near the front wall, one to 8′-7 3/4″ for the corner near the rear wall, and another to 11′-7″ for use as a starter trim board at the base of the side wall.

13.2 Fasten the vertical 1x3s at the front and rear corners with 2” galvanized nails or weather-resistant trim-head screws. Then install the starter trim board at the base of the wall using the same fasteners.

13.3 Next, cover the wall with 6” bevel siding, as shown in the illustration below, nailing it to the wall studs.

13.4 Be sure to leave a 1 ft. sq. opening in the siding for ventilation.

13.5 Repeat the above procedure to put siding on the opposite side wall.

Step 14: Installing the Exterior Siding to the Back Wall

14.1 Cut pressure-treated 1x3s to make trim boards for the rear wall. Using the illustration below as a reference, cut two 1x3s to 9′- 1″ for the vertical ends of the wall, and one 1×3 to 15′-8 1/2″ for the starter trim board along the base of the rear wall.

14.2 Fasten the vertical 1x3s at the corners with 2” galvanized nails or weather-resistant trim-head screws. Then install the starter trim board at the base of the wall using the same fasteners.

Prepare and install starter course 15′-8 1/2″ long from the pressure-treated lumber with cross section 1/4″ x 3/4″ (node B on page 20).

14.3 Install the exterior siding using 1/2″ x 6″ siding boards in accordance with the illustration below.

Step 15: Installing the Exterior Siding to the Front Wall

15.1 As with the previous two steps, cut pressure-treated 1x3s to make trim boards for the two corners and base of the front wall. Using the illustration below as reference, cut two 1x3s to 8′-1″ and one to 15′-8 1/2″.

15.2 Install 15′-8 1/2″ long starter trim board along the base of the wall.

with cross section 1/4″ x 3/4″ (node B on page 20).

15.3 Next, install 6″ siding to the wall in accordance with the illustration below.

15.4 Then, trim around the door opening with pressure-treated 1x3s, as shown in the illustration.

15.5 You will need two 1x3s cut to 5′-9″ and two cut to 6′.

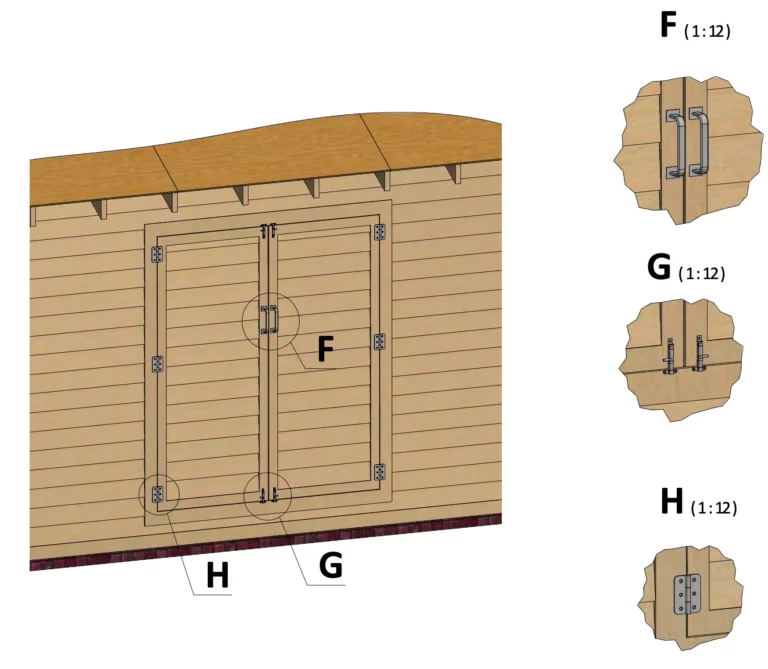

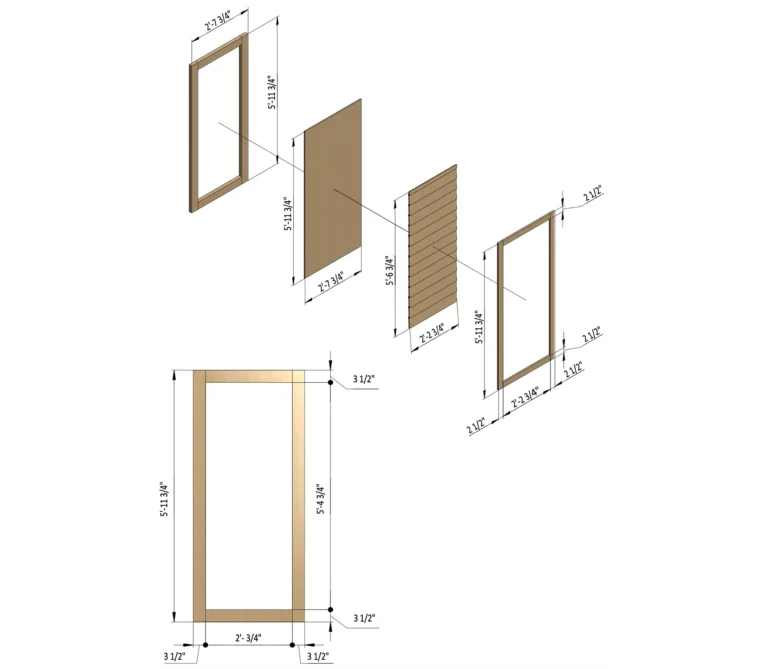

Step 16: Assemble and Install Shed Doors

16.1 Build the door frames for the shed using pressure-treated 2x4s. For each door, cut two 2x4s to 5′-11 3/4″ for the vertical stiles, and two 2x4s to 2′-3/4″ for the horizontal rails. Screw together the door frames with 5” screws.

16.2 Cut two pieces of 5/8″ plywood to 2′-7 3/4″ x 5′-11 3/4″, one for each door.

16.3 Cut four lengths of pressure-treated 1x3s to create trim for the rear of each door. Cut two 1x3s to 2′-2 3/4″ and two more to 5′-11 3/4″.

16.4 Lay the 5/8” plywood panel on one of the door frames, set the rear trim on the plywood. Drive 2” screws through the trim, plywood and into 2×4 door frame.

Using 1/4″ x 3/4″ pressure-treated lumber, cut and install a starter course 2′-2 3/4″ long using Node B on page 20 as a reference.

16.5 Now cut 6″ siding to fit within the 2×4 frame on the face of each door, as shown in the illustration below.

16.6 Secure the siding with 1 1/4″ galvanized nails.

16.7 Hang each door with three 3″ hinges. Finish the door installation by attaching four 4″ slide-bolt latches and two 6″ door pulls (see nodes F, G, H).

Step 17: Assembling the Shed's Roof Fascias

17.1 Cover the underside of the rafter tails with a pressure-treated 1×8 soffit, as shown below. Then, rip a 1×8 to 6” wide and fasten it across the ends of the rafter trails to create a fascia board.

Step 18: Shed's Side Wall Ventilation

18.1 Install 12″ x 12″ louvered vent in the openings of side walls.

18.2 Secure the vent 2″ screws.

Step 19: Roof Sheathing Installation

19.1 You will need about 235 Sq Ft of asphalt shingles to cover the shed’s roof.

19.2 Start by installing aluminum drip-edge flashing to the edge of the roof.

19.3 Cover the entire roof with felt building paper, then nail down the asphalt shingles.

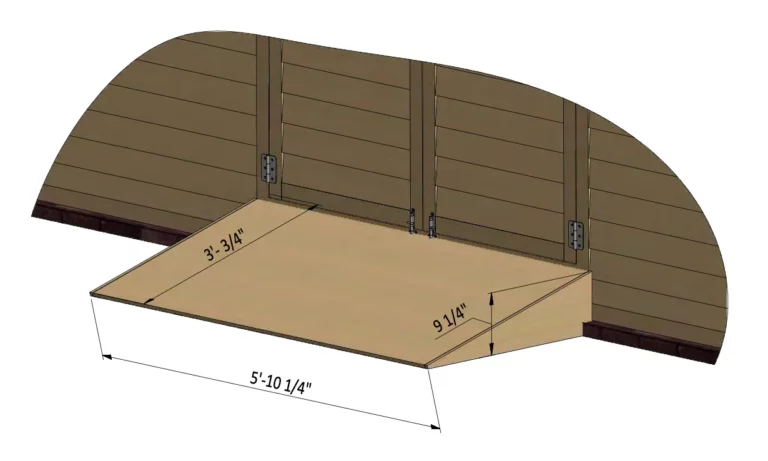

Step 20: Assemble and Install Door Ramp

20.1 Use pressure-treated lumber to build a ramp for easy access into and out of the shed. The ramp consists of five triangular frames that get covered with plywood. For each frame, cut one 2×2 to 1′-8″, one 2 x 3 to 3′-3/4″ and one 2×4 to 6 1/4″.

20.2 Fasten together each frame using 3″ and 5″ screws (node K on page 29). 20.2 Join the frame together with a 2×3 cut to 5’-9″ long; fasten it to the frames with 3″ screws.

20.3 Next cut a piece of 5/8″ plywood to 3′-3/4″ x 5′-9″ for the top surface of the ramp. Then cut two triangular pieces of ⅝” plywood to 9 1/4″ x 2′-9 1/2″ to cover each end of the ramp.

20.4 Attach the plywood to the ramp’s frame with 2″ galvanized nails.

Step 21: Shed Decoration

Now that your shed is all done, you are ready to decorate it any way you want using your favorite paint, stain, or clear wood preservative.