Types of Fasteners: Understanding Screws, Nails, Bolts, and Anchors

Hanging framed photos on your walls or assembling furniture? Installing flooring or replacing missing roof shingles? All of these tasks require the use of fasteners — but which kind do you need for the work you’re doing?

You might not realize just how many types of fasteners are available. Some, like nails and screws, are used for everyday projects. Others, like carriage bolts and lag screws, are used for heavy-duty work, such as vehicle assembly and construction. And within each fastener category, you’ll find several different kinds to choose from.

We’ll go over the different types, including subtypes, and give you some tips on how to choose and use fasteners for your project.

What Are Fasteners?

As the name implies, fasteners are pieces of hardware used to fasten or secure materials or objects together. Some are designed for permanent use. Others you can easily remove, if necessary.

Fasteners can be used on virtually any type of building material, including wood, plywood, plastic or metal. This makes them an ideal solution when adhesives alone, such as glue or epoxy, just aren't strong enough.

What Are Different Types of Fasteners?

Fasteners come in many types, shapes, and sizes. This gives you a big selection to choose from — no matter what type of work you’re doing or what project you’re planning. Let’s take a closer look at the different kinds of fasteners.

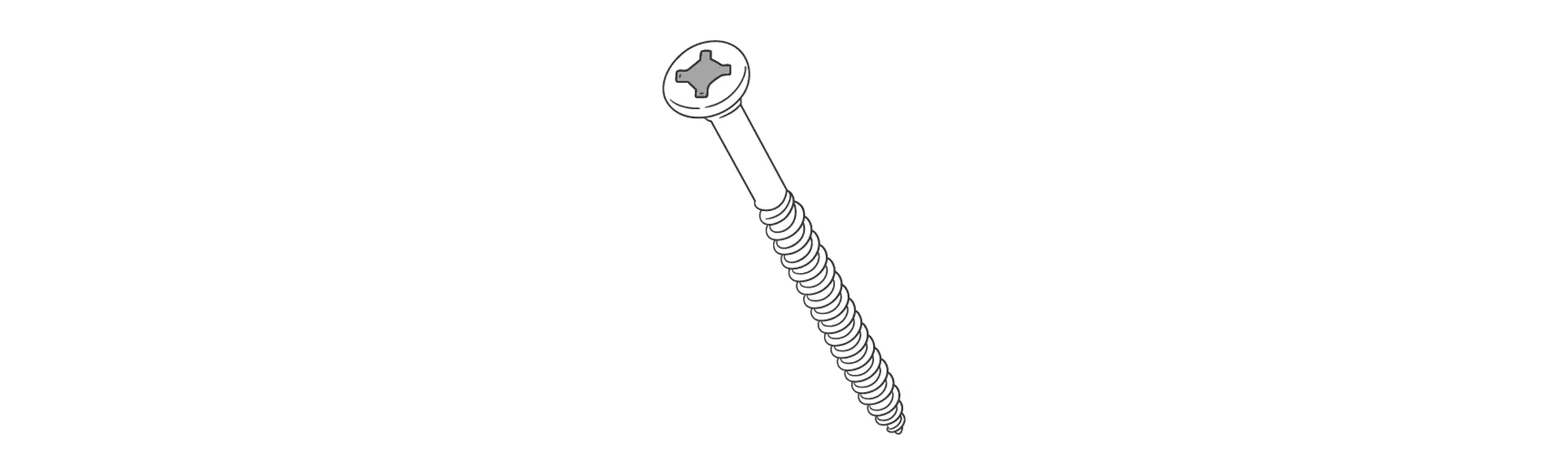

Screws

These fasteners have spiral threads cut into their shanks. They can be used with many kinds of materials, and come in several lengths, diameters, and types of heads.

Depending on the job, you can use a manual screwdriver, power drill, wrench or ratcheting socket wrench to secure them. Some screws are self-tapping, meaning that they can make their own hole as you screw them into a material.

Screws have various types of heads, such as flanged, flat, pan, oval, and round. The type that you’ll need will depend on what you’re using it for.

Different types of screws include the following:

- Wood screws: Choose these if you’re working with any kind of wood or a material that’s similar to wood— that’s what they’re made for. Wood screws have flat heads and sharp, tapered points that easily punctures wood. And the upper shank of a wood screw is not threaded, allowing it to pull the top board down tightly to the bottom board. Most wood screws are Phillips head screws, but slotted and square-drive are also common. When using wood screws, be sure to drill a pilot hole first to lower the risk of splitting the board.

- Deck screws: These exterior-grade screws are corrosion resistant to prevent rusting. They're used to build decks, fences, patio furniture, and other outdoor projects. They have flat heads, thin shanks, and deep, aggressive threads, for quickly power-driving them into place.

- Drywall screws: These uncoated steel screws are similar to deck screws. They have flat heads, thin shanks and deep threads. As the name implies, drywall screws are designed for hanging drywall, but they're also great for all sorts of woodworking and construction projects. Just be aware that they aren't corrosion resistant and will rust if used on an outdoor project.

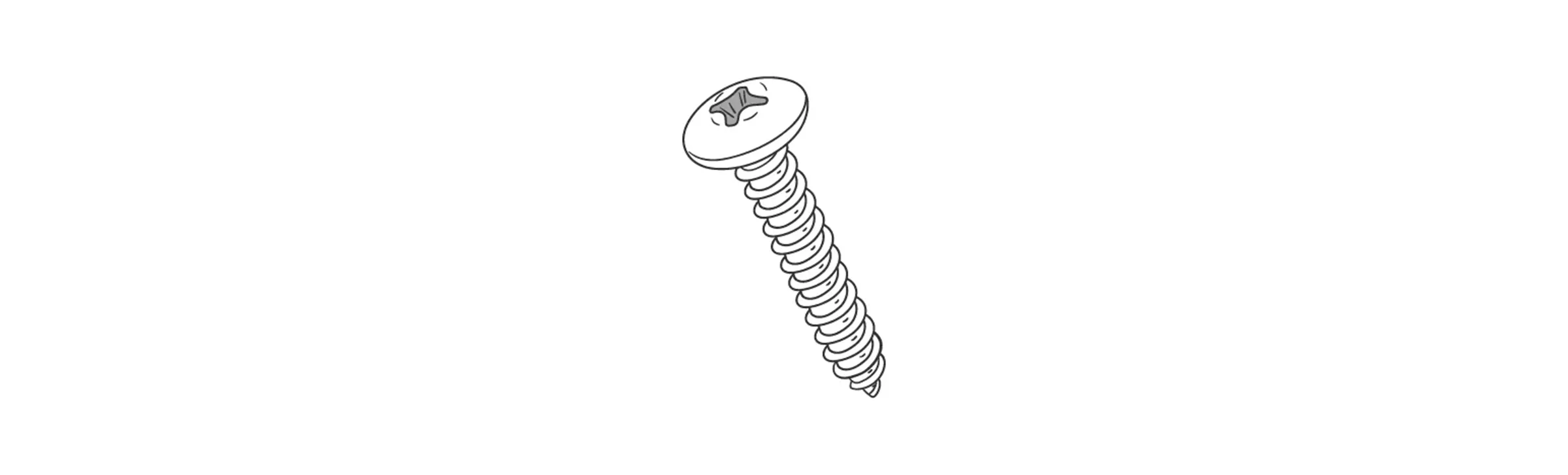

- Machine screws: Unlike wood or drywall screws, the shank of a machine screw has machine threads to accept a hex nut. They’re commonly called through bolts because they all the way through the two pieces being joined together. They can be used for fastening together wood or metal components. For outdoor projects, be sure to use machine screws that have a weather-resistant zinc-galvanized coating.

- Sheet metal screws: These pan-head screws are fully threaded--from tip to head--and are meant for joining together metal. However, they can also be used to fasten together plywood. These self-tapping screws are available in dozens of lengths and diameters.

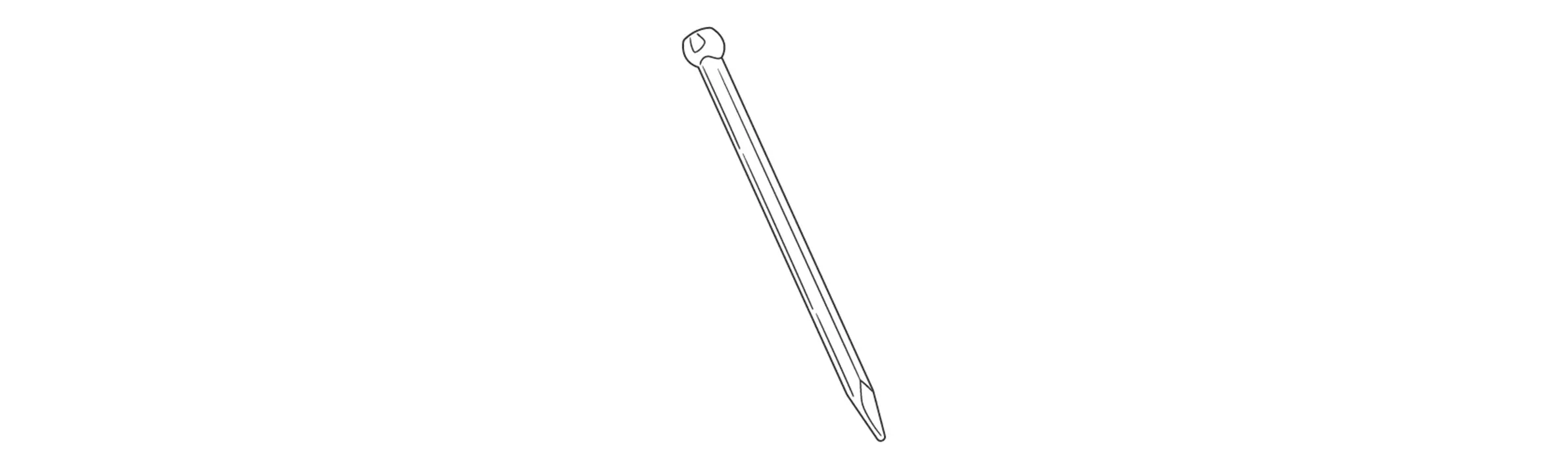

Nails

Nails represent the world's oldest fasteners, dating back more than 5,000 years to Ancient Egypt. Today, nails are still popular for joining together wooden parts. Most nails have smooth shanks, but others are ring- or barb-shanked to increase the holding power. And while screws provide good tensile strength or the ability to hold objects together, nails have better shear strength — or the ability to handle pressure from two objects sliding by each other.

Nails also cost less than screws, making them cost-effective. But it’s important to make sure they’re the right type of fastener for your project. For example, nails tend to be a better choice for roofing applications compared to screws.

Nails come in many types and can be used for all kinds of purposes. Different types of nails include the following:

- Box nails: These nails have a thinner shank and less strength than other nails, such as common nails. Their thinner shape means they have a lower risk of splitting wood. Many are resistant to corrosion, making them a good choice for outdoor applications.

- Brad nails: Looking for nails to use on decorative pieces of wood? Brad nails don’t stand out as much from an aesthetic standpoint compared to other nails. They’re also smaller than other nails and have tiny heads, making them ideal for use on wood trim and similar wood pieces.

- Common nails: These are the go-to nails for many carpentry and construction projects. Common nails have a large, round head and thicker shank. This design makes them a good choice when a lot of support is needed, such as with framing.

- Drywall nails: These nails have a large, very flat heads and often rings on the shaft. The rings help stop them from working loose. These are designed for hanging drywall.

- Finishing nails: Need nails that won’t show in molding or other structures? Finishing nails have a thin design and small heads that you can sink below the surface, making them much less visible than other nails.

- Flooring nails: Installing or repairing flooring? That’s what these nails are made for. Some flooring nails have a spiral shank to lower the risk of slipping. Other flooring nails have a ringed shank that holds them securely in place when used for subfloors or plywood flooring.

- Roofing nails: These nails have a very broad, flat head and thin shank. This allows them to securely hold asphalt shingles to the plywood roof sheathing. Some roofing nails have a ringed shank, but all are corrosion resistant to deter rusting.

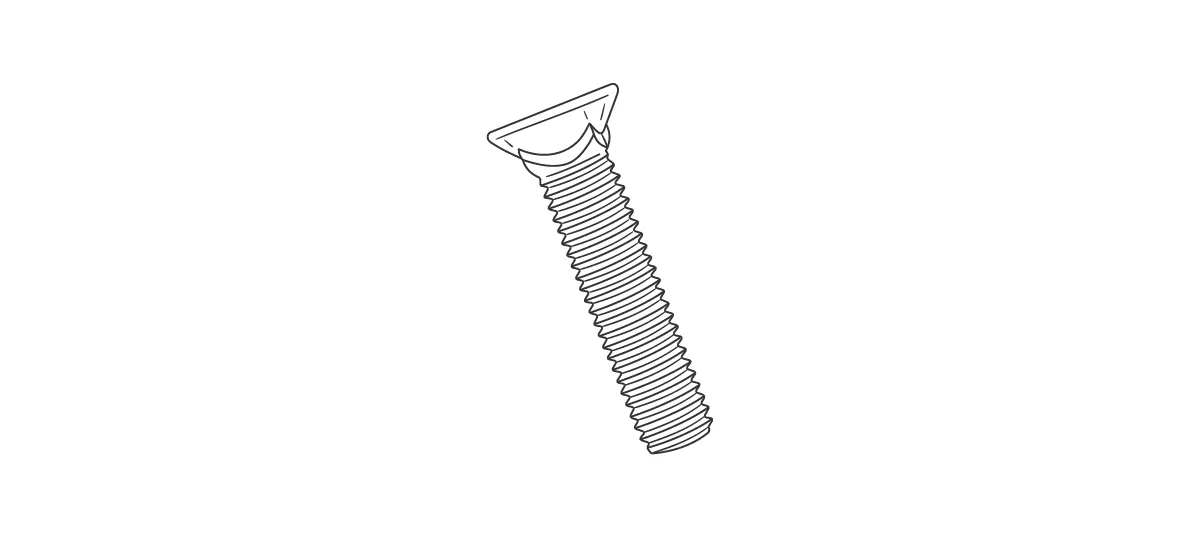

Bolts

Some bolts have wood-screw threads, others have machine threads that accept a hex nut. Bolts come in different sizes based on their length and shank diameter. They can be used with several kinds of materials and for many different projects. And most types are available with a corrosion-resistant finish for use on outdoor projects. When using bolts, you’ll need to make sure you also have compatible nuts.

Different types of bolts include the following:

- Carriage bolts: These machine-screw bolts have a large, dome-shaped head. Directly below the head, at the top of the shank, is a square shoulder that helps lock the bolt in the hole. Use carriage bolts to join together wood or metal pieces.

- Eye bolts: These machine-screw bolts don't have a head, per se, but instead a large circular eye that's are suitable for anchoring, hoisting, or similar applications.

- Flange bolts: These bolts are able to distribute loads more evenly than other bolts due to their circular-shaped flange at base of the hex-shaped head.

- Lag bolts: These bolts have hex-shaped heads, thick shanks and wood-screw threads. They’re a good choice if you’re doing decking framing or building with large, thick timbers.

- Plow bolts: Plow bolts have machine-screw threads and flat heads that sit flush with the surface, making them less visible than other kinds of bolts.

- Hex-head machine bolts: These bolts feature a hex-shaped head, making them easier to work with when using wrenches or ratchets. They're also available with square heads.

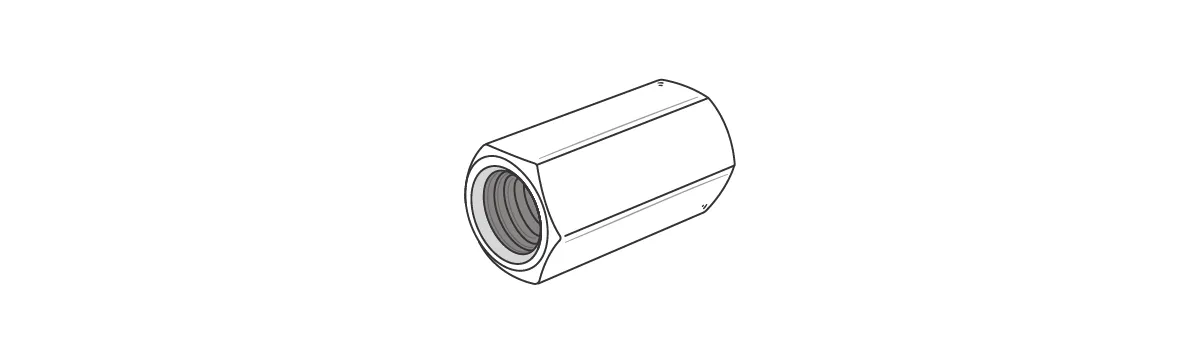

Nuts

Nuts are used with fasteners that have machine-screw threads. The center hole of each nut is tapped with threads to match the machine-screw threads. Nuts come in many different sizes and threads, so be to choose the right nut for the fastener you're using.

Several kinds of nuts are available, including the following:

- Cap nuts: These nuts have a domed top and are used to cover the ends of the machine-screw shank.

- Coupling nuts: These are hollow nuts that connect two male nut threads together. They’re also known as extension nuts.

- Hex nuts: These nuts have internal threads and six sides. They’re used for many applications and come in several types, including semi-finished, slotted, finished, and hex flange.

- Lock nuts: Use these hold-tight nuts when there's a risk of the nuts working loose due to vibration or constant twisting. These nuts are also called nylon lock nuts.

- Slotted nuts: These nuts are used with a cotter pin to ensure the nut can't loosen up. They have slots across the top of the nut for this purpose.

- Speed nuts: These nuts have two metal pieces that work as one piece. They’re also known as sheet metal nuts.

- Square nuts: These square nuts are often chrome plated.

- Lug nuts: These nuts are used to secure wheels to a vehicle.

- Wing nuts: These nuts have wings on either side, so they can be manually tightened or loosened.

Washers

Washers are sometimes the third type of fastener used along with nuts and bolts. They can also be used with screws. They’re a flat, circular-shaped fastener with an open center hole. One is typically placed under both the hex nut and head of the fastener. Why use them? Washers are designed to distribute loads evenly for improved security.

Washers can reduce the risk of corrosion and ease friction while maintaining the right amount of tension. When using washers, you’ll need to choose the right type that’s compatible with the nuts and bolts or screws you’re using.

- Beveled washers: These washers provide better support and stability when you need to join surfaces together that aren’t parallel.

- Flat washers: These kinds of washers are thinner and rounder than others. But they do come in a variety of thicknesses to fit different bolts. They’re good for general use and are the most common type of washer.

- Lock washers: These washers help hold fasteners in place better when there’s more risk of rotation or loosening due to vibration. Different kinds of lock washers include split lock, internal tooth lock, and external tooth lock.

- Structural washers: Need washers for heavy-duty use? That’s what structural washers are for. These are thicker than other kinds of washers.

- Torque washers: These are often used with carriage bolts, especially for carpentry and construction projects. The washers have a square center hole to accept the square shoulder on the carriage bolt, and sharp prongs that stop the bolt from spinning as the nut is being tightened.

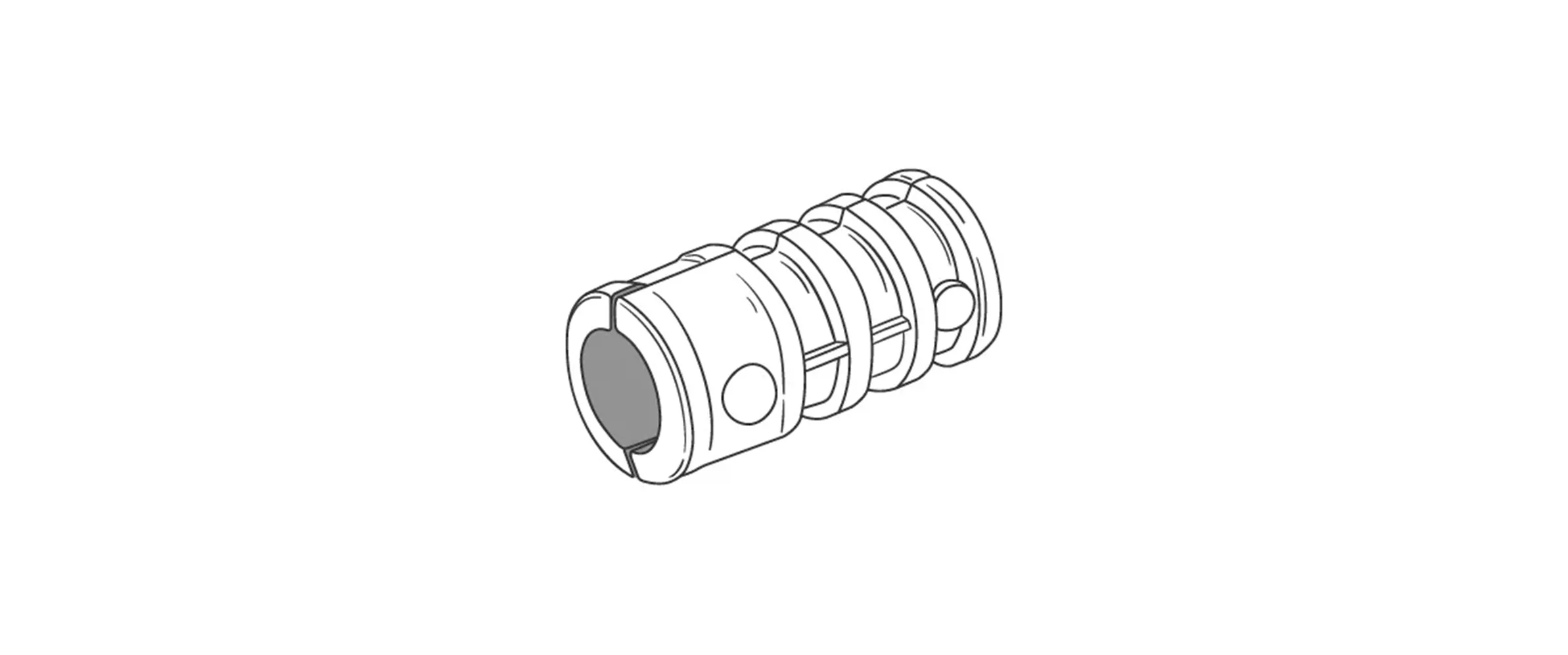

Anchors

Anchors are fasteners used for holding an object or material to a thicker or stronger material, like concrete. Anchors can keep objects or materials securely in place to reduce the risk of having them come loose or fall. For example, you might use anchors for securing a large-screen TV to your wall rather than relying on screws or other fasteners.

When using anchors, always consider the type of load these fasteners can handle. You’ll also need to consider the load capacity. Otherwise, anchors may not be able to hold the object in place. You can find light-duty, medium-duty, and heavy-duty anchors.

Different types of anchors include the following:

- Masonry screws: These are medium-duty anchors that are good for joining electrical boxes and similar items to brick, concrete, or other masonry materials. They come with either flat heads or hex heads and feature high and low threads that tighten into a predrilled hole.

- Lag shields: These are another medium-duty anchor type. You can use them in hard masonry materials, depending on their length. Choose longer lag shields for tougher materials and shorter lag shields for softer or shallower materials.

- Plastic wall plugs: These are light-duty anchors that you’ll need a hole for. You can use these for hanging small framed photos or similar items on walls.

- Sleeve anchors: These are medium-duty anchors that you can use for installing railings or other structures on concrete and other materials. They have sleeves that grip the inside of the hole and become tighter as you tighten the anchor.

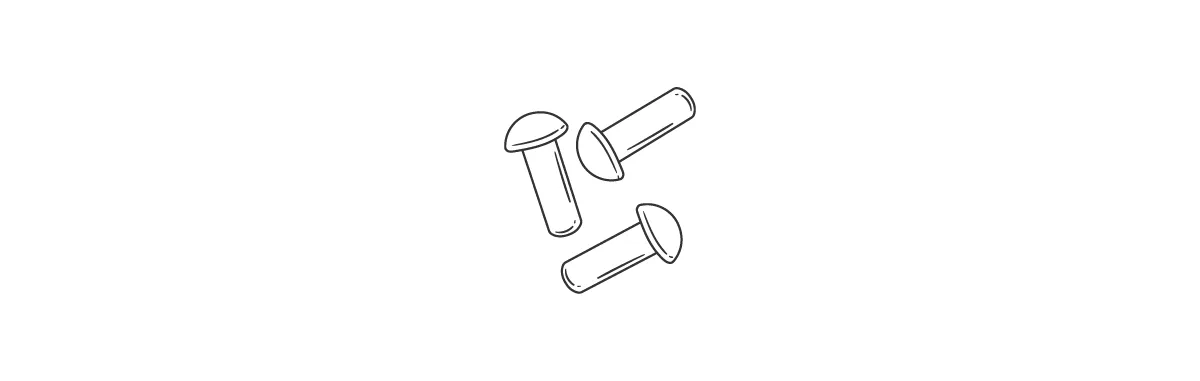

Rivets

Rivets are fasteners with a head, tail, and cylindrical-shaped shaft. Rivets tend to be more durable than other types of fasteners, making them a good choice for heavy-duty work. They require the use of a special tool to make the tail wider.

Rivets are widely used in certain industries, including the automotive and steel industry, due to the ability to make permanent connections between materials or objects. They can’t be taken out or used again once they’re secured.

Different types of rivets include:

- Pop rivets: These rivets have a tubular sleeve fitted over a metal pin. They're installed with a pop rivet gun and are used to join together thin pieces of metal.

- Semi-tubular rivets: These have a hollow body that gets larger when heat is applied.

- Solid rivets: These are often used for constructing aircraft due to their solid design and incredible durability.

FAQs About Fasteners

What is the most common type of fastener?

Screws are generally considered the most commonly used fasteners. Their variety of lengths and types means you can use them for all sorts of projects. You might use tiny screws to hold electronics together. Or you might use larger and more durable screws for securing drywall.

What is the strongest type of fastener?

Commercial Grade 8 bolts are typically considered the strongest due to their tensile strength. They can handle 150,000 pounds per square inch (psi) — that’s a lot of pressure that these bolts are able to withstand!

Tips for Choosing Fasteners

How do you know if you’re using the right type for the job? We’ll go through some helpful tips on selecting fasteners. Consider these factors before choosing a type:

- Material: What materials are you joining together? Make sure the materials you’re joining and the fastener can be used together.

- Strength: How much pressure strength and load-bearing strength do they require? Figure out how much tension and weight they’ll need to be able to handle.

- Size and shape: What is the material type and thickness? This helps you determine the length, thread, and diameter of the fasteners you need to use.

- Appearance: Consider this if fasteners are going to be visible.

- Installation: How easily can you access the area where fasteners are going? Consider using self-tapping screws or similar fasteners in hard-to-reach areas, for example.

- Environmental factors: Do they need to be resistant to corrosion? Marine grade fasteners offer this resistance. Also consider other relevant factors, depending on your project, such as temperature, UV exposure, and chemical exposure.

Now you understand the basics of fasteners — so you can choose the right kind for your project. Make sure you also use the right tools to secure them, such as a hammer for common nails or a screwdriver for screws. As always, wear protective safety gear if needed to reduce your risk of injuries.